Hanneng Vacuum Brazing Machine

Hanneng Co. Ltd is the pioneer in the development of vacuum-pumping equipment in Taiwan. Hanneng were the first in Taiwan to provide professional design and manufacturer in vacuum-pumping machine.

Their experts fully put theory into practice to design and produce competitive high-end vacuum pumping machines. The vacuum pumping machine can be used in the production processes of various high-tech materials, such as sintering, brazing, refining, melting, metallic heat treatment, diffusion welding, PVD/CVD, etc. We work very closely with customers, customizing the machine and manufacturing process according to their needs. Our ultimate goal is to provide our customers with a high-quality vacuum system to produce products with high stability, based on our many years of research, innovative spirit and many years of experience in product and product development.

As part of our service, we also provide our customers with a complete process plan, quality control, after-sales repair and maintenance services to increase their competitive advantages.

The Hanneng vacuum brazing furnace not only produces large quantities of products with stable quality, but is also versatile to meet different customer requirements.

Less deformation during the brazing process leads to less wear on the cutting plate and lower costs. Our sensors detect the presence of abnormal conditions and power outages. All information from the sensors is integrated into the information system.

The total processing time for a finished workpiece is only about 1 hour (depending on the part), making it significantly more economical and sustainable than conventionally heated furnaces.

two versions are currently available:-

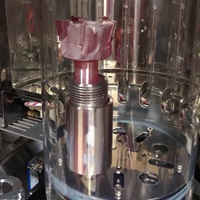

VBF-6H Horizontal

Or

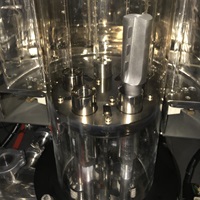

VBF-6F Vertical

The vacuum chamber is arranged vertically and equipped with an automatic turntable. This makes the system more efficient for rotary tools of larger dimensions. Solutions for partial heating to protect HSK, for example, are also optionally available.

Technical Specification

Horizontal Version – VBF-6H

Inner diameter of vacuum chamber: 150mm

Quartz glass holder: 175 x 130mm

Maximum height: 75mm

Vertical Version – VBF-6F

Inner diameter of quartz glass chamber: 150mm

automatically rotating Stainless steel holder

Maximum height: 400mm

General information

● Max. Vacuum: 10-6 torr

● Max. Temperature: Approximately 920 °C

● Temperature Control Precision: ±3°C

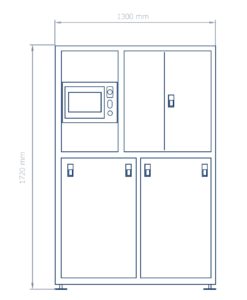

● Size (Horizontal Version): 1300 x 700 x 1720 mm

● Size (Vertical Version): 1100 x 1100 x 1850 mm

● Weight: 550kg

● Power Supply: 3 x 220V/N + PE 65A / 100A – 60Hz

● Power Consumption (H/V): Max. 24/33kW

● Heating Power (H/V): 18/27kW

● Compressed Air Supply: 6 bar

● Cooling: Water cooling via regulated circuit

with external cooling unit (19200BTU/h)

Outline Dimensions