Coborn PL Series

PL4/5i Planetary Lapping Machines for PCD

Coborn’s planetary lapping machines are designed to polish the top surface of PCD discs to a flat, mirror finish. They can also be used to polish CVD discs and PcBN.

The machine consists of a number of independent work heads which hold the discs against a large, horizontally mounted planetary motion grinding wheel.

It is impossible to use flood cooling when polishing large areas of PCD as the discs ‘aqua-plane’ on the wheel surface. Therefore, the lapping is a dry process and the wheel is internally cooled using water from an associated water chiller.

Chilled water is also fed to the back of each disc. This maintains the disc at a uniform temperature to minimize disc dishing.

The PL4i can be equipped with up to 5 work heads.

The larger PL5i can be equipped with up to 6 work heads.

Each arm is fitted with a double gimbal fixture to allow the disc to self-level. The disc holders are motor driven.

The lapping pressure can be individually adjusted.

The lapping or polishing of the top surface of PCD or CVD components is desirable to produce a smooth surface for chip flow and a good cutting edge for geometric integrity. It also maximizes edge life, enhancing the characteristics of PCD and also minimizes surface deviations over a large PCD or CVD area.

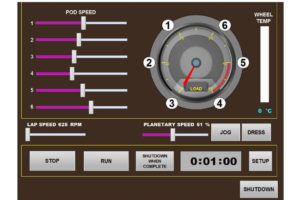

The PL5i has a new user-friendly touchscreen control system providing more clarity on display status and more detailed diagnostics. New features include spindle load monitoring and the planetary wear indicator.

Specifications

PL4i

Machine dimensions (w x d x h):

690mm x 1,020mm x 1,625mm

Machine weight: 550kg

Main spindle: 12.0 kW

Chiller capacity: 7.5kW

Fixtures: up to 5 can be fitted

Wheel: Diameter 300mm, Face 45mm

PL5i

Machine dimensions (w x d x h):

790mm x 1,150mm x 1,625mm

Machine weight: 590kg

Main spindle: 12.0 kW

Chiller capacity: 7.5kW

Fixtures: up to 6 can be fitted

Wheel: Diameter 450mm, Face 105mm

Technical Details

| Characteristic | PL4i | PL5i | |

|---|---|---|---|

| MACHINE | |||

| – Machine type | Planetary lapping machine | Planetary lapping machine | |

| – Dimensions (w x d x h) | 690mm x 1020mm x 1625mm | 790mm x 1150 x 1625mm | |

| – Total machine weight | 550kg | 590kg | |

| SPINDLE | |||

| – Spindle type | Coborn precision spindle | Coborn precision spindle | |

| – Main spindle power | 12.0kW | 12.0kW | |

| PLANETARY WHEEL MOTION | |||

| – Planetary wheel motion | Variable stroke between 9.5mm and 22mm in 24-0.5mm steps |

Variable stroke between 9.5mm and 22mm in 24-0.5mm steps |

|

| POLISHING STATION FIXTURES (ARMS) | |||

| – Number of fixtures | up to 5 can be fitted | up to 6 can be fitted | |

| – Motorised drive to disc holders | Yes | Yes | |

| – Self levelling disc holders (gimbals) | Yes- double gimbal | Yes – double gimbal | |

| – Water cooling to disc holders | Yes | Yes | |

| – Independent timers | Yes – one | Yes – one | |

| – Polishing pressure | Individually adjustable | Individually adjustable | |

| – Maximum load per station | 56kg as standard (128kg on request) | 56kg as standard (128kg on request) | |

| – Maximum permissible total load (all stations) | 250kg | 300kg | |

| – Maximum disc size | 45mm PCD on 45mm wheel | 100mm PCD on 105mm wheel | |

| WHEEL (Resin bonded Diamond) | |||

| – Wheel diameter | 300mm | 400mm | |

| – Wheel face width | 45mm or as requested | 105mm or as requested | |

| CHILLER | |||

| – Capacity | 7.5kW | 7.5kW | |

| – Chiller dimensions (w x d x h) | 715mm x 715mm x 1375mm | 715mm x 715mm x 1375mm | |

| – Chiller weight | 190kg | 190kg | |

| ELECTRICAL REQUIREMENTS | |||

| – Electrical Requirements | 3 phase, 415v or 220v | 3 phase, 415v or 220v | |