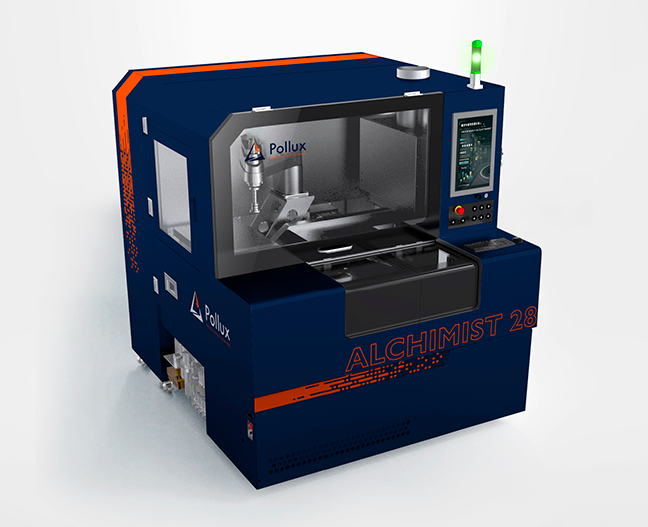

Pollux Alchimist 28

CNC Peripheral grinding machine for Carbide, cermet, CBN and PCD inserts

Ultra compact 4-axis grinding center with loading robot, state-of-the-art control and drive technology, stable machine base, no superstructures or attachments, all units as well as the electrostatic oil mist separator are integrated into the machine. We deliver complete turnkey including coolant filtration system. All you need to do is add the grinding oil you want and you can start making money right away.

Precision-Enhanced

Tailored for indexable tungsten carbide inserts with seamless in-process dressing

capabilities, ensuring precision even for Cermet, CBN and PCD.

Sturdy Foundation machine bed

Crafted with an artificial marble and cast iron base for durability and low thermal

expansion.

Next-Gen Motor Technology

Digital water-cooled AC motor for the Spindle, and a modern digital AC Servomotor

for B-axis as well Linear motors for X and Y-Axis.

State-of-the-Art Control Units

Machine control by Germany’s renowned Bosch Rexroth.

Robot control expertise from Japan’s Nachi.

Stable temperature conditions with a dedicated air/water heat exchanger.

Technical Specification

Machine dimensions (w x d x h) – 790mm x 2017mm x 1900mm

Machine weight – 5 Tons

CNC control system – CNC control by Germanys renowned Bosch Rexroth

Grinding wheel spindle – 9.0kW 0 – 3600 rpm programmable

Grinding wheel – Ø 350mm